Sustainable Sneakers

Course:

Instructor:

Student Name:

INDS 3397 | Sustainable Design (Full Course)

Min Kang & Jeff Feng

Zola

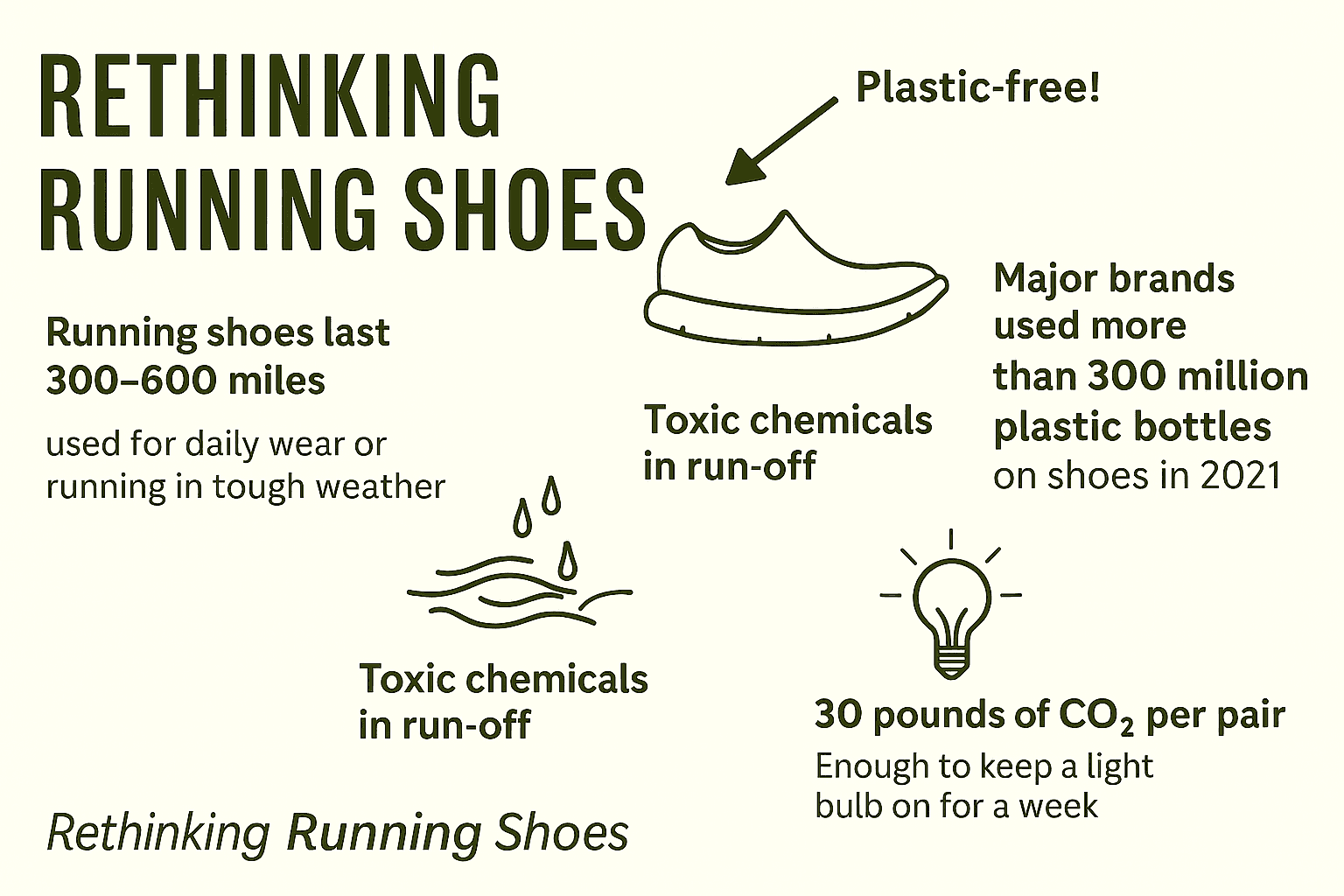

This project investigates the environmental impact of running shoes—from production to disposal. With lifespans of just 300–600 miles, sneakers contribute significantly to plastic waste, toxic runoff, and CO₂ emissions. Major brands used over 300 million plastic bottles for shoes in 2021 alone. By highlighting these issues, the project calls for plastic-free design, circular systems, and greater consumer awareness to reduce the footprint of everyday footwear

What We Offer

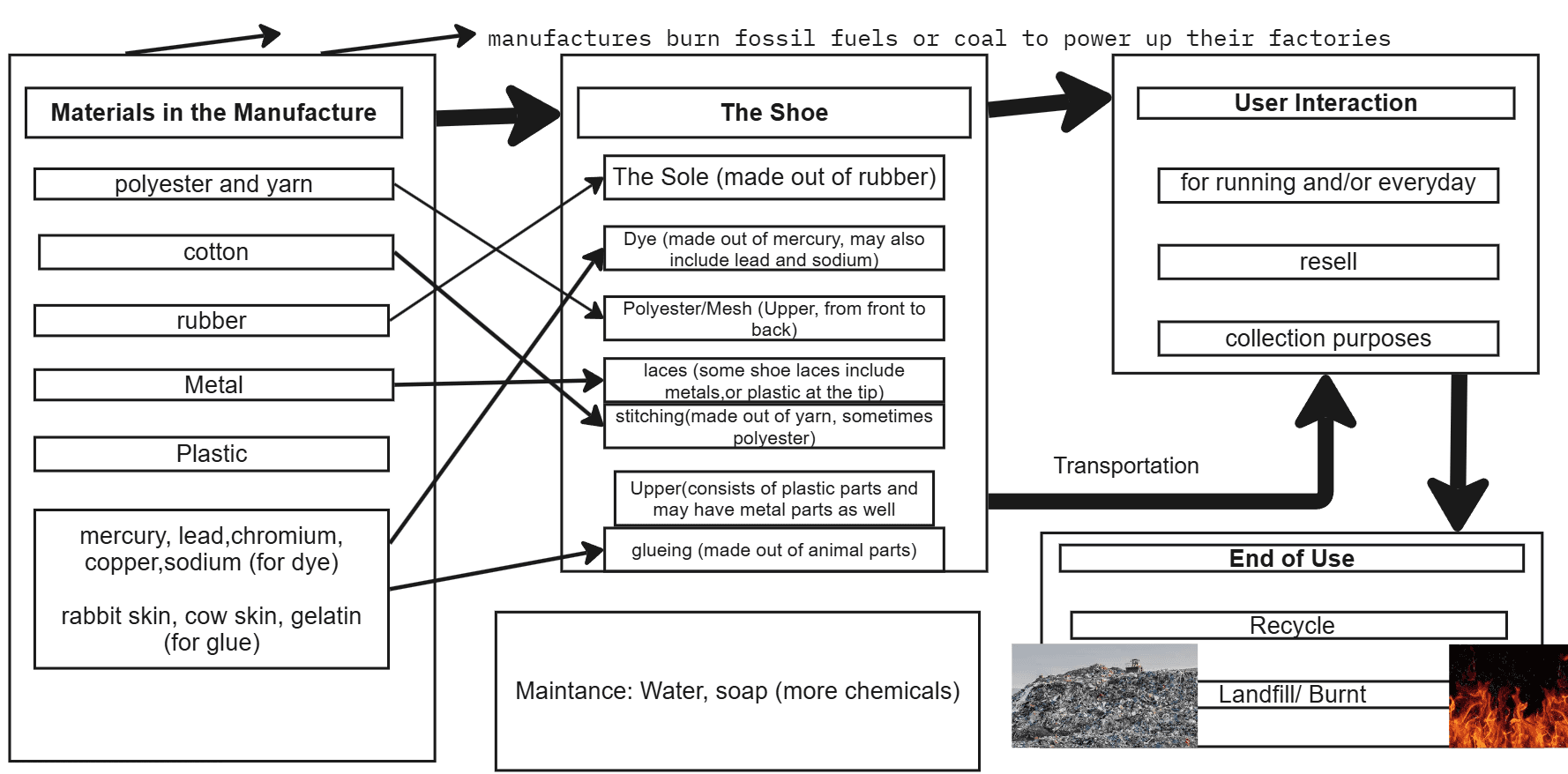

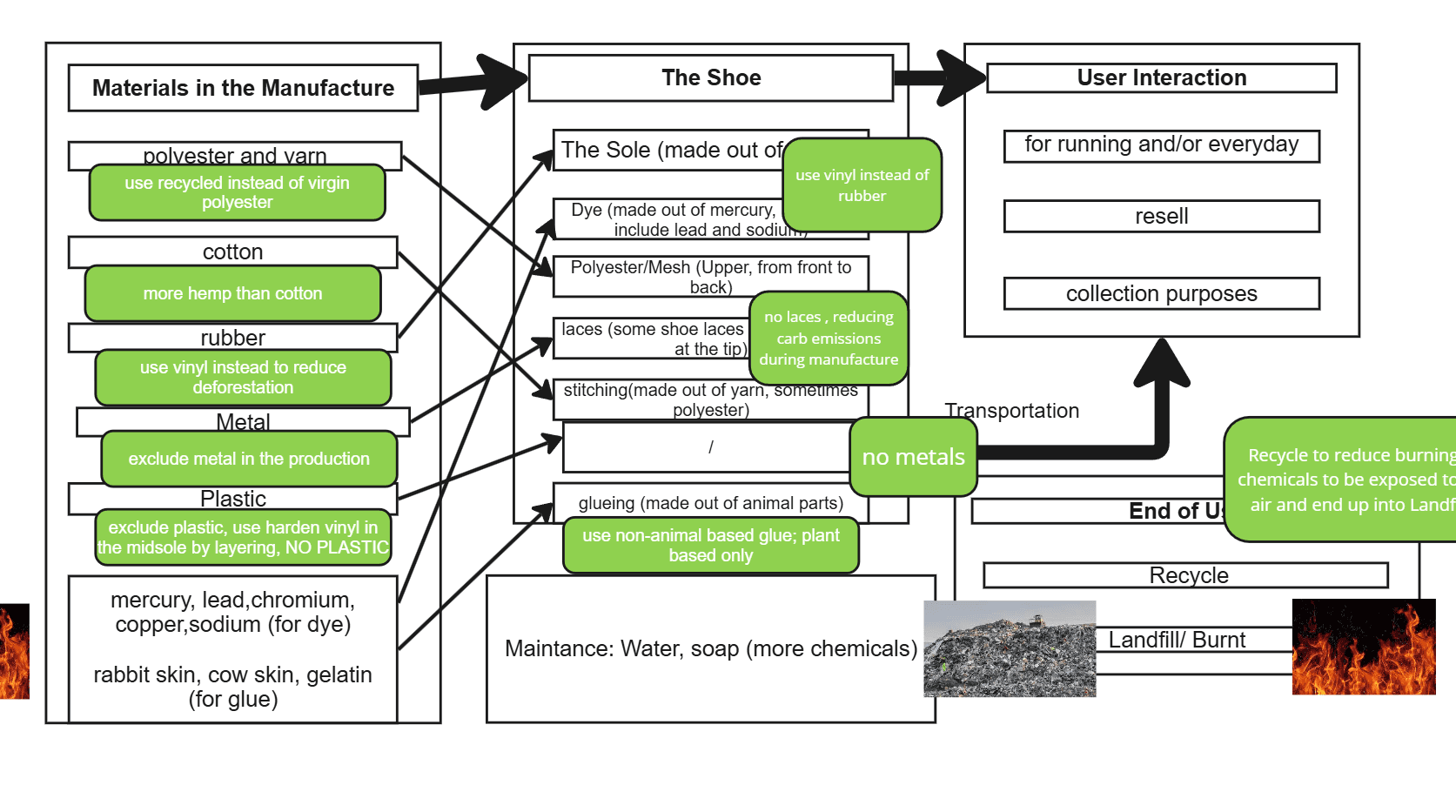

From fossil-fueled factories to toxic dyes and animal-based glues, every step in a shoe’s lifecycle leaves a mark. Materials like polyester, rubber, and metals contribute to pollution, while disposal often means landfill or incineration. Even maintenance adds chemical waste. This project exposes the complex footprint behind everyday footwear—and calls for cleaner, circular design.

Measuring Sustainability

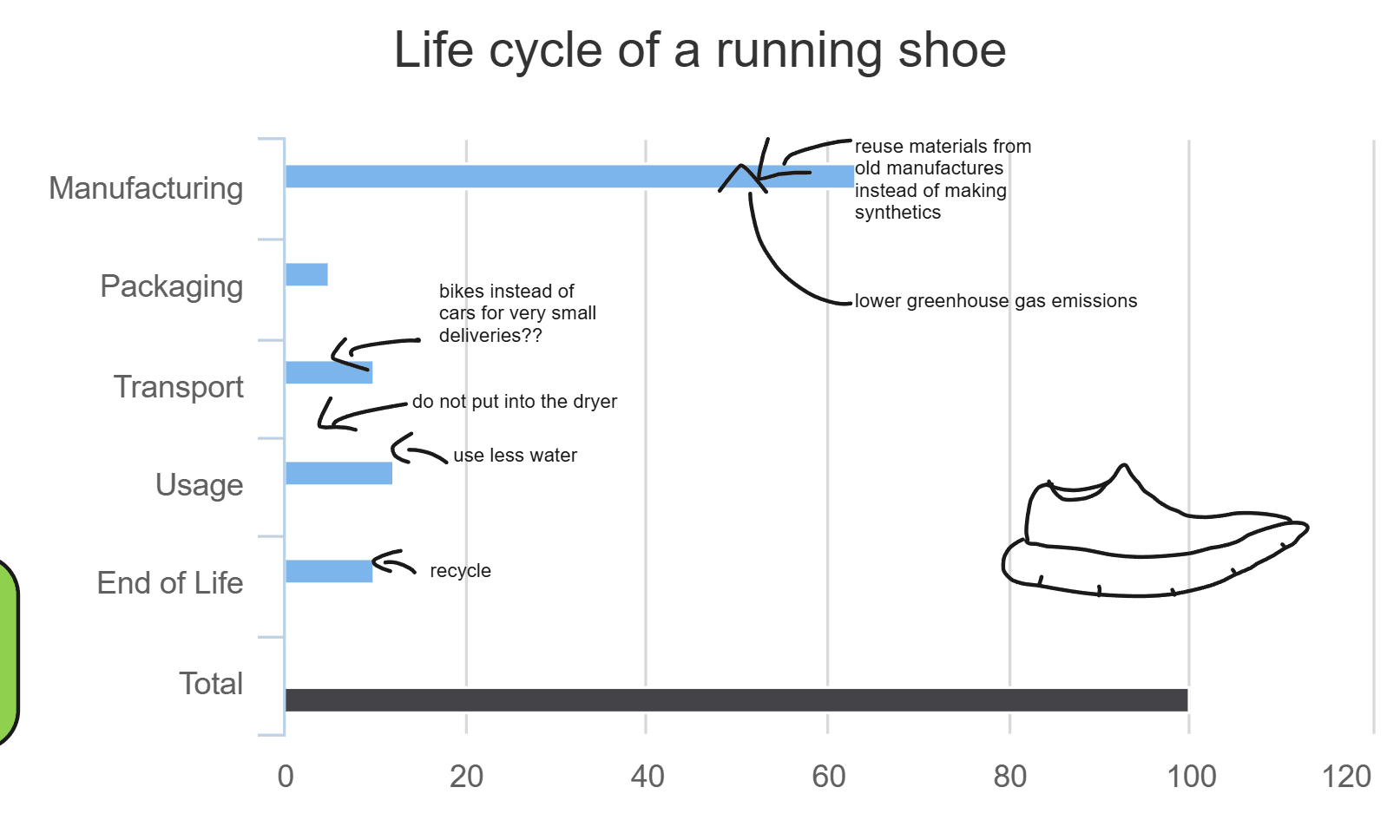

Manufacturing is the biggest environmental burden in a running shoe’s life—followed by transport and usage. From fossil-fueled production to water-heavy maintenance, each stage adds emissions. Bean to Green promotes reuse, recycling, and low-impact design to shrink this footprint from start to finish.

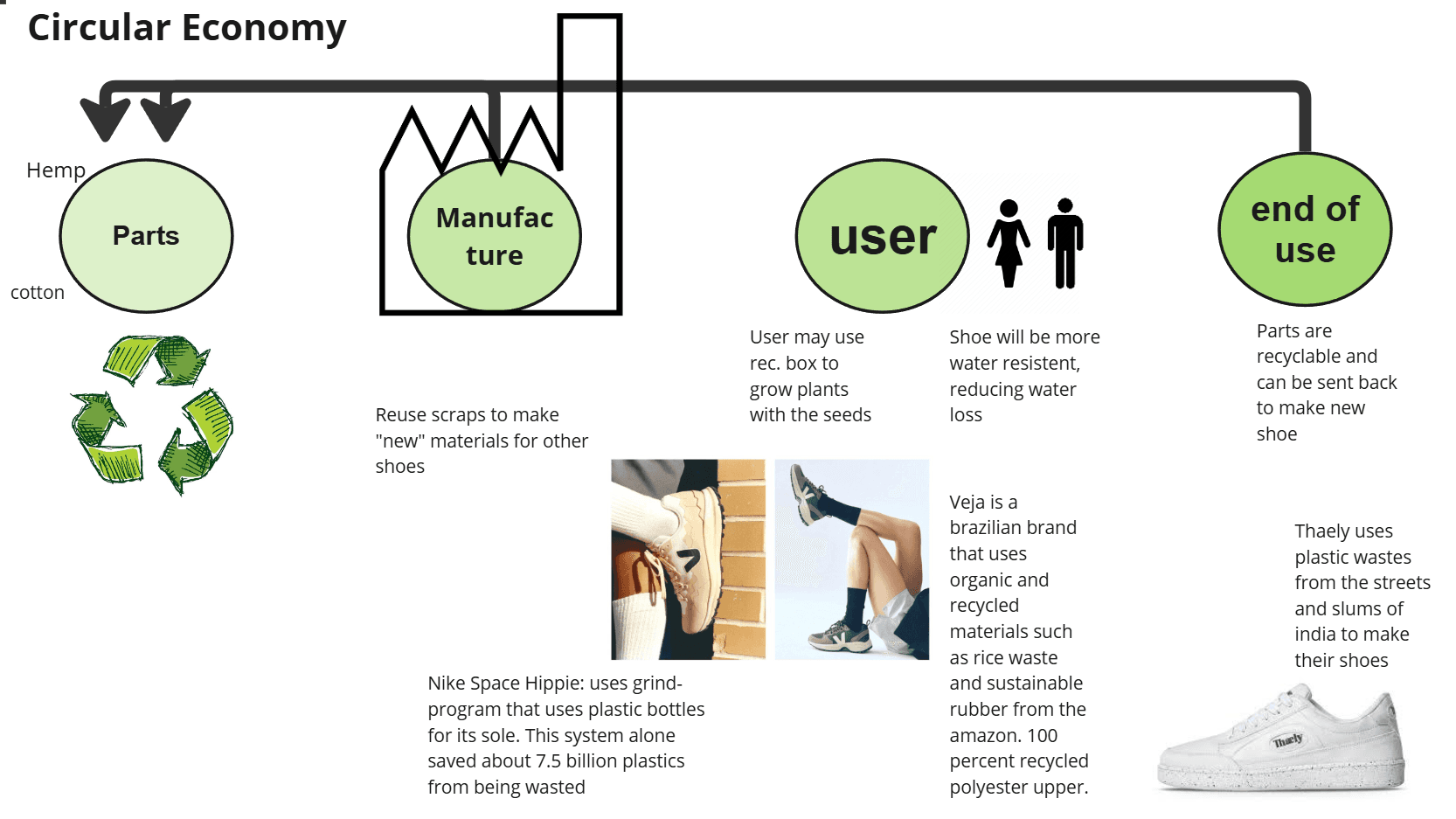

This model reimagines footwear from the ground up—using hemp, cotton, and recycled materials to reduce waste. Brands like Veja and Nike Space Hippie lead the way with biodegradable packaging, sea-sourced plastics, and organic components. At end-of-life, shoes are collected, recycled, and reborn—closing the loop and keeping waste off the streets.

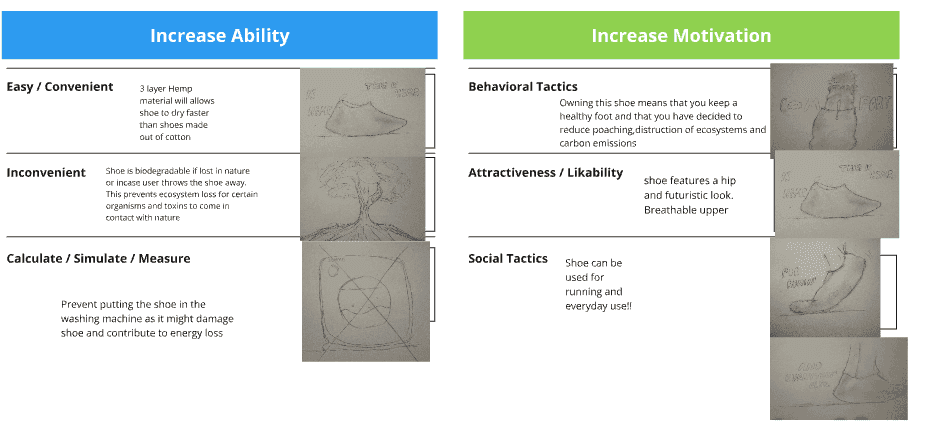

Sustainable shoes must balance ease and appeal. While hemp-based materials offer eco-friendly convenience, concerns about durability in rain or washing can reduce trust. Motivation grows when shoes feel stylish, support healthy habits, and fit everyday life.

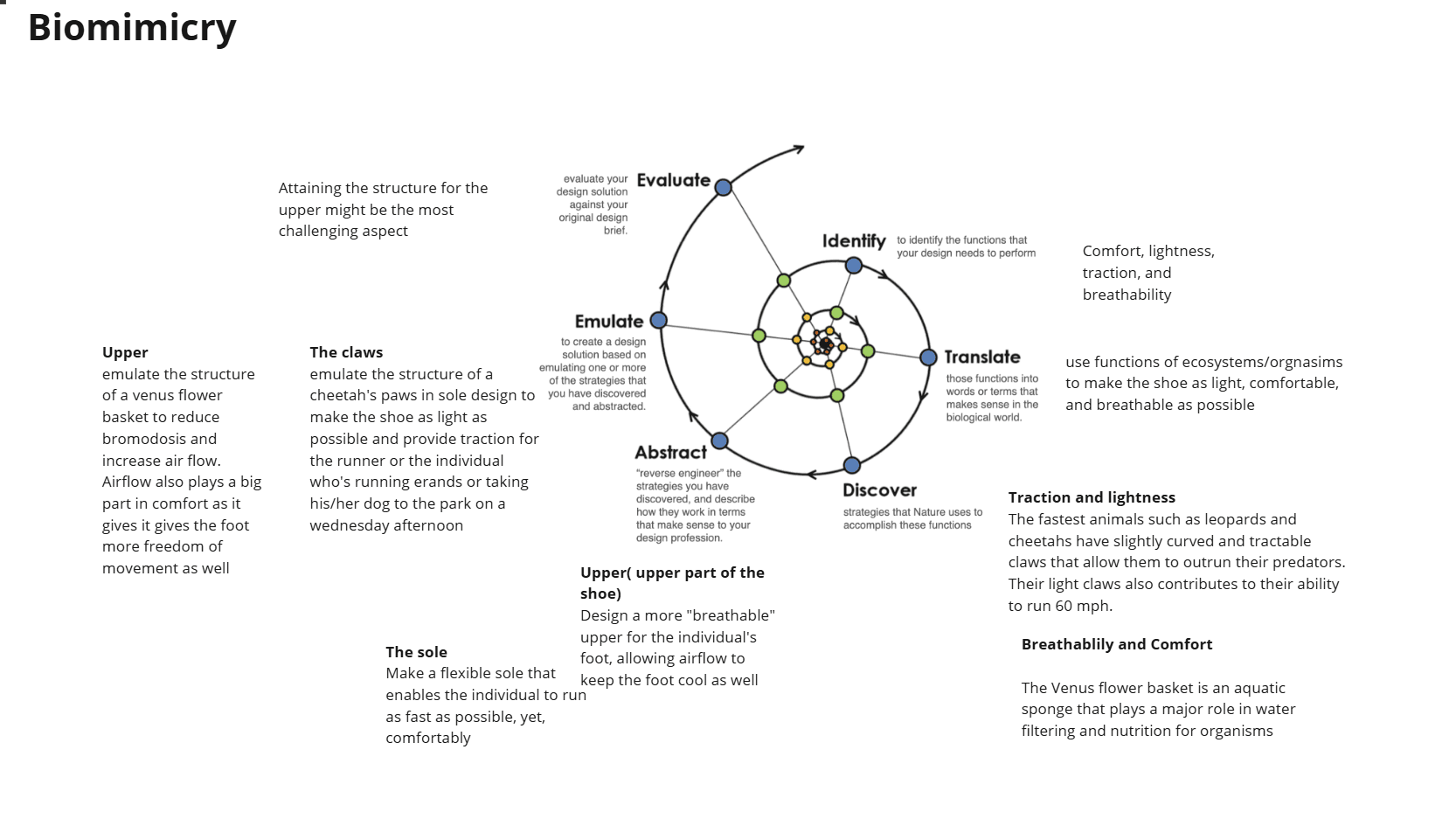

This concept reimagines footwear through biomimicry—drawing from cheetah paws for grip, airflow, and agility, and the Venus flower basket for breathability. Using a six-step design loop (Identify, Translate, Discover, Abstract, Emulate, Evaluate), it blends natural efficiency with human comfort. The result? Shoes that feel fast, light, and alive